Interrogators

September 17, 2021 2023-08-09 17:14Interrogators

Lenterra Optical Interrogators (LOI)

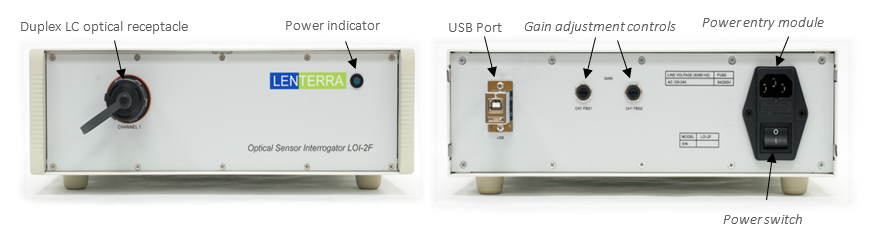

Lenterra Optical Sensor Interrogator (LOI) is a compact, robust, fast measurement unit designed for the high resolution interrogation of optical sensors (Fiber Bragg Grating or Whispering Gallery Mode sensors) in laboratory or industrial environments.

LOI utilizes fast, low noise Distributed Feedback diode laser with narrow linewidth for full spectrum scanning. Adjustable photodiode gains allow for measurement of returned light intensity in a wide dynamic range. LOI is controlled by any standard PC through USB interface. The unit can be used with third party FBG or WGM sensors as well as with Lenterra’s RealShear™ and DFF sensors for measurements of such parameters as wall shear stress, drag force, temperature, strain, viscosity and others.

Depending on configuration, LIR consists of one or two Lenterra’s sensors (Drag Force Flow (DFF) or RealShearTM), an LOI optical interrogator and a host computer with control, measurement and data processing software. The probe placed in a desired location within the processing equipment is connected to the interrogator via fiber-optical cable. To install the probe into an apparatus, an adapter is required.

There are two basic types of LIR configurations that are determined by the type of the interrogator – a one channel LOI-2F and a two channel LOI-4F. There are total of six different configurations of LIR specified below. They are customizable, and could be converted one into another by replacing the sensor. Each configuration includes a rugged laptop pre-installed with measurement and post processing software. The LENFLOW measurement software supports all LIR configurations.

LOI-2F

This basic LOI configuration includes one DFF sensor that can be placed in various places inside the processing equipment, for example next to an agitator blade of a mixer as depicted in the figure. Depending on the flow speed and nature of the material, a DFF sensor with required sensitivity should be selected. A standard or custom adapter can be used, See available adapters here.

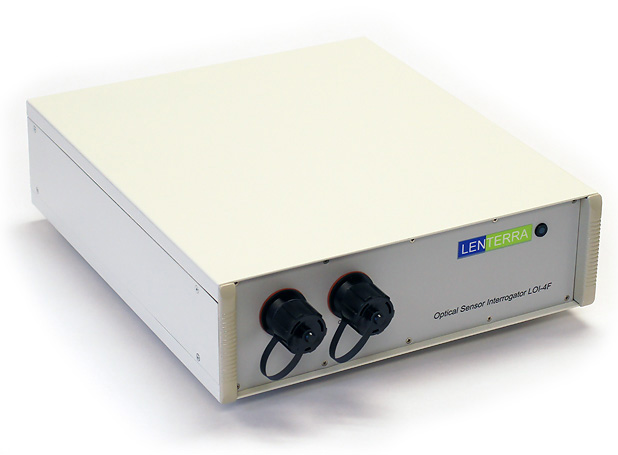

LOI-4F

This basic LOI configuration includes one DFF sensor that can be placed in various places inside the processing equipment, for example next to an agitator blade of a mixer as depicted in the figure. Depending on the flow speed and nature of the material, a DFF sensor with required sensitivity should be selected. A standard or custom adapter can be used, See available adapters here.

Specifications

| Model | LOI-2F | LOI-4F |

|---|---|---|

| Mechanical, Environmental, Electrical Properties | ||

| Length | 40 cm (15.5") | 47 cm (18.5") |

| Width | 30 cm (11.7″) | |

| Height | 10.5 cm (4.2″) | |

| Weight | 4.7 kg (10.4 lbs) | 6 kg (13.2 lbs) |

| Voltage requirements | 100-240 VAC @ 47-63 Hz | |

| Operating temperature | From 0°C to 40 °C | |

| Storage temperature | From -10 °C to 50 °C | |

| Optical Properties | ||

| Light source | DFB diode laser | |

| Central wavelength | 1540-1560 nm | |

| Linewidth, FWHM | <10 MHz | |

| Scan range: | ||

| via laser temperature1 | 3.7 nm | |

| via laser current1, 2 | 1.2 nm | |

| Scan rate: | ||

| via laser temperature1 | 0.1 nm/s | |

| via laser current1 | from 0.33 nm/s to 650 nm/s | |

| Scan frequency (via laser current)3 | from 0.25 Hz to 500 Hz | |

| Wavelength increment1 | ||

| at 0.25 Hz | 0.8 pm | |

| at 10 Hz | 0.8 pm | |

| at 100 Hz | 0.7 pm | 1.6 pm |

| at 500 Hz | 2.9 pm | 5.4 pm |

| FBG spectrum tracking repeatability1,4 | ||

| at 0.25 Hz | 0.5 pm | |

| at 10 Hz | 0.3 pm | |

| at 100 Hz | 0.2 pm | |

| at 500 Hz | 0.4 pm | |

| Number of optical channels | 2 | 4 |

| Connector | Duplex LC/PC | Two FC/APC |

| Photodiode amplifier gain | 105, 106, 107 V/A | |

| Data Processing Capabilities | ||

| Interface | USB | |

| Software type | LabVIEW based data acquisition and control software | |

| Software capabilities | Spectra recording, spectra averaging, spectra tracking, differential spectrum (between channels 1 and 2) tracking, data logger, instrument control | |